Fake Solar Panels

- SolarKobo

- Nov 8, 2021

- 6 min read

Updated: Nov 10, 2021

On February 2, 2020, PV Magazine reported that thousands of solar panels from Italy that were being sent for recycling were instead smuggled to Syria and Africa. They were illegally re-badged and resold to countries including Nigeria. In the wake of the operation code-named 'Operation BlackSun' during which the racket was carried out, Italy’s Carabinieri Command for the Protection of the Environment would seize the waste treatment plant where the panels were being sent. The owner of the plant was also arrested and another 60 tons of panels were found on the premises.

It has been almost two years since the report was published but anyone who is well aware of local realities can expect those solar panels to still be in the market. This means that every untrained buyer if not just the unsuspecting ones, should assume that he/she is at the risk of being coaxed into investing in fake solar panels and take appropriate steps to mitigate the risk.

What is a Fake Panel?

By definition, a fake solar panel is a panel that come with faults in its design or defective components and as such do not have the specified power production capacity, or any power production capacity at all. Fake panels contain elements which are not solar material, but have been added to increase the size of the panel, to create the impression that the capacity is larger than it is, or to hide defects in the module. A fake panel would contain counterfeit or poorly-made labels or spec sheets, which would contain counterfeit names, false compliance to testing standards, incorrect panel ratings, and other misleading information.

The influx of fake solar panels into the local markets are majorly due to these two reasons:

Human factors like poor efforts by regulatory bodies and authorities. Nigerian and African markets are generally susceptible to the influx of substandard products for this very reason. In most African countries, Nigeria included, fake panels are considered national problems.

Also, the increasing demand for solar products creates the opportunities for the spread of fake solar panels.

In fake solar panels, the following defects may be immediately visible.

1. Physical Defects

Fake solar panels and their components are manufactured using substandard materials like 'seconds', that is, wafers that have been rejected by the top manufacturers. In some cases, they can just be used solar panels that were rebadged.

Physical defects include broken parts, rusted parts, browned spots, a string of cracks on the surface of the panels, faulty junction boxes, etc.

More on this Subject: Common Defects in Solar Cells.

2. Cracks and Chips

Cracked and flaked solar cells on solar modules often indicate the manufacturer has used lower grade solar cells. Breakages could also be occasioned by a manual soldering process, which is a common practice in the manufacture of fake solar panels. The automatic soldering process minimizes breakages. Also, breakages can be occasioned by a manual cutting process. The best manufacturers use laser beams to cut the silicon ingots into wafers used in making the cells.

Since most counterfeits are shipped secretly to avoid being detected by authorities, and because they are not properly handled when in storage, this increases the likelihood of the solar cells breaking while on transit. Also, the presence of small foreign particles such as soldering debris and wire inside the solar module is also a telling sign of a sub-standard solar panel.

3. Colour Variations

Variations in colour imply that the solar cells used in the manufacture of the panels were mismatched. While a mismatched solar cell string alignment may not necessarily affect the solar module’s performance or lifespan, it can indicate a phony manufacturing process. Proper alignment of cells is an easy thing to do and if a manufacturer cannot get it right it means there are other important parts of the device that could be defective.

4. Scratches On the Panel Glass

Scratches on the glass cover of the solar panel may mean that the panel was not properly handled at the factory or that it was hastily and insecurely stored away. However, it could also be that the panels were made from low quality glass. Solar panels are encapsulated in a tempered glass panel. This special glass panel is made to be scratch-proof. Scratches on the panel glass suggests sub-standard manufacture. While small scratches can be expected to cause slight shading on the cells, large and deep abrasions will certainly compromise the their ability to produce electricity. In the case where everything else has been accounted for, abrasions should sound out alarms. The dealer should be able to offer explanations if he cannot offer a replacement panel.

5. Absence of Labels, Serial Numbers and Barcodes

Every solar panel must have a spec sheet on its backsheet. The only exception is in the case where the solar panel is considerably small. An absence of a spec sheet, without any doubt, implies a sub-standard manufacture. Moreover, the information provided on the spec sheet is needed to properly install and use the panel and the absence of this information is a potential safety issue.

According to IEC standards, manufacturers are required to ensure that every solar module has a barcode and serial number behind the glass. The goal of the barcode is to help track the device through production and assembly and afterwards, its warranty. Suppliers of fake solar panels try to circumvent this by fixing illegible or broken barcodes on the back of a device.

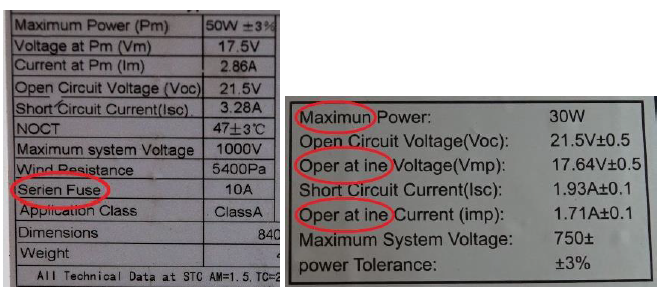

6. Damaged Spec Sheets, Incorrect Information On Spec Sheets.

Spec sheets are made with weather- and handling-resistant materials, in the best cases at least. They are also have to be attached properly to not peel or bubble easily.

Wrong information provided on the spec sheet should sound out alarms as should typographical errors on the spec sheet. The spec sheet often contains valuable information about the operating parameters of the panel. Its tells much about the panel's electricity production capacity, its efficiency, information about the control tests it had passed before being introduced into the market and other information that relates to how it operates under changing temperatures. These information are a very part of a solar panel.

Any solar panel without a spec sheet or with typographical errors, ineligible lettering or bubbles in the spec sheet and spec sheets that have peel off point to a substandard manufacture or counterfeit.

Also Read: Common Defects in Solar Panels.

7. Giveaway Pricing

Solar panels account for between 45-60% of investments in a solar electricity system. Sellers of fake products often offer their products at a giveaway price. This is what makes them very attractive. But solar panels like all good products come with monetary value that must be respected by the buyer.

8. Fake Frames

To protect them from damage and to hold them in place, solar panels are encased within a metal structure frame. When manufactured with substandard materials, this frame would be weak or damaged or rusted.

Fake panels are in no way easy to spot; it takes circumspection, keen eyes and knowledge of what a real panel looks like. Circumspection means assuming that anyone can fall victim to those who hustle panels on e-commerce sites and in open markets. Sellers of fake products are often always in a hurry to close a deal. This means that buyers should be on the lookout for anything that looks suspicious and be willing to be petulant with too many questions if they find any. Or to just leave at once.

In this article on the subject, we summarise the parameters we use to identify the best brands of solar panels. While those considerations are helpful in a situation where the only consideration is performance not quality, in situations where quality is paramount and fake products are common, however, they may not be very helpful because those who sell fake solar panels rebrand them with those reputable brand names to befool unsuspecting buyers.

The best protection against buying fake products is to buy from well-known, reputable and authorised dealers. A reputable brand name is as good as the reputation of the dealer. In the solar industry, reputation is key. A dealer must be willing to invest in his reputation by sourcing his products from the top manufacturers, by running a website with clear and verifiable contact information or operating an office in a known location, by properly handling his products when in storage, by being willing to return them if the buyers find them defective, etc. Hustlers are mostly unwilling to do these things: they try instead to sweet-talk or pester their buyers into giving up their money and then disappearing into thin air.

SolarKobo helps its clients make the best possible choice of solar panels, inverters, batteries and charge controllers. We also have university-trained engineers who offer high-value installation services on order.

Comments